The global trend of increasing customer requirements in terms of quality, determines us to establish as a main concern obtaining, maintaining and continuously improve the quality of services and products, all achieved by offering competitive prices.

Aiming this, we focus all our efforts to establish and maintain relationships with all customers and to open new markets, having Quality as our strength.

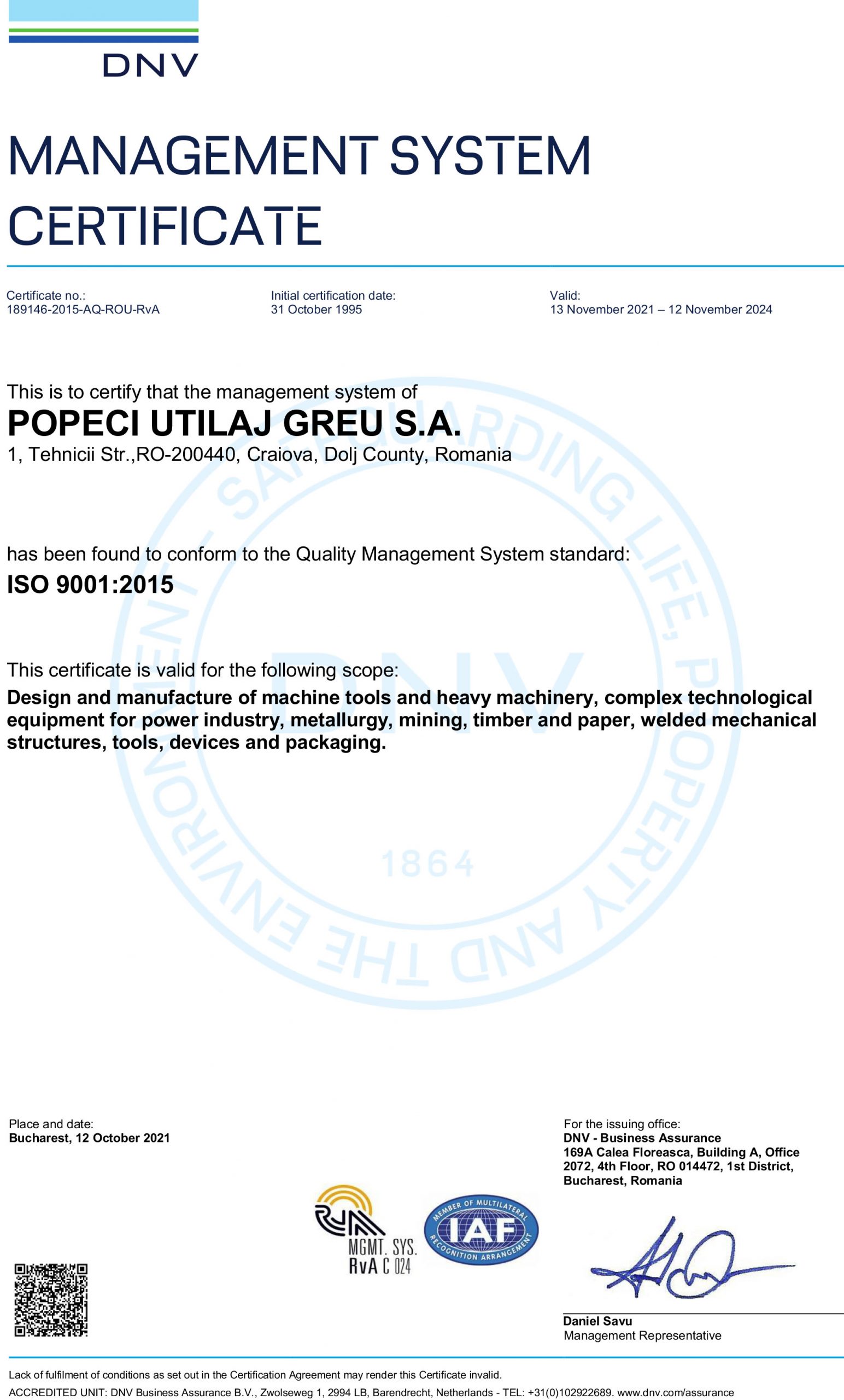

The company’s policy in the field of quality is to pursue a total customer satisfaction, in conditions of intense competitive environment, and the implementation and maintenance of the Quality Management System showed us how we can perform, so as to offer customers best quality products and services.

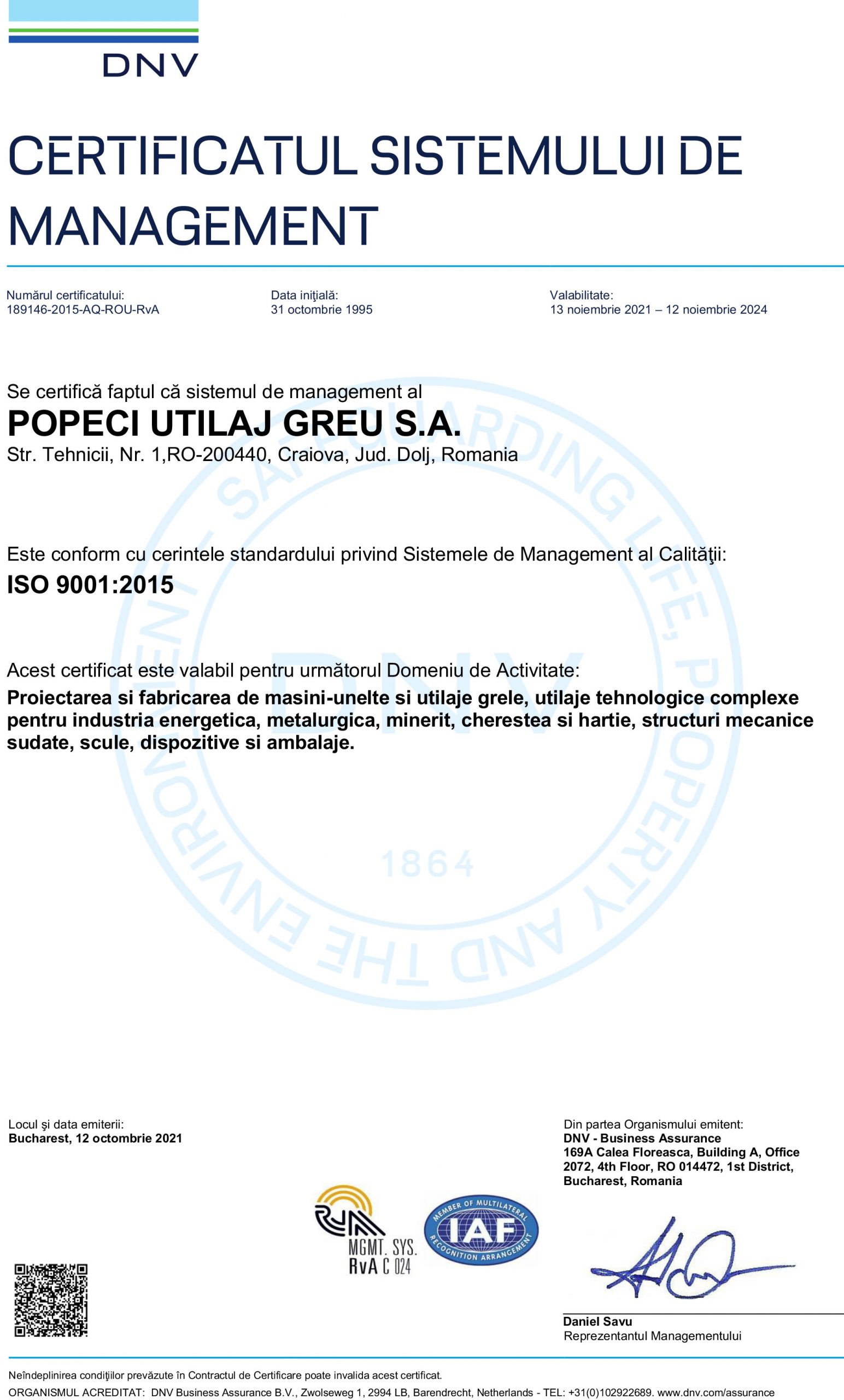

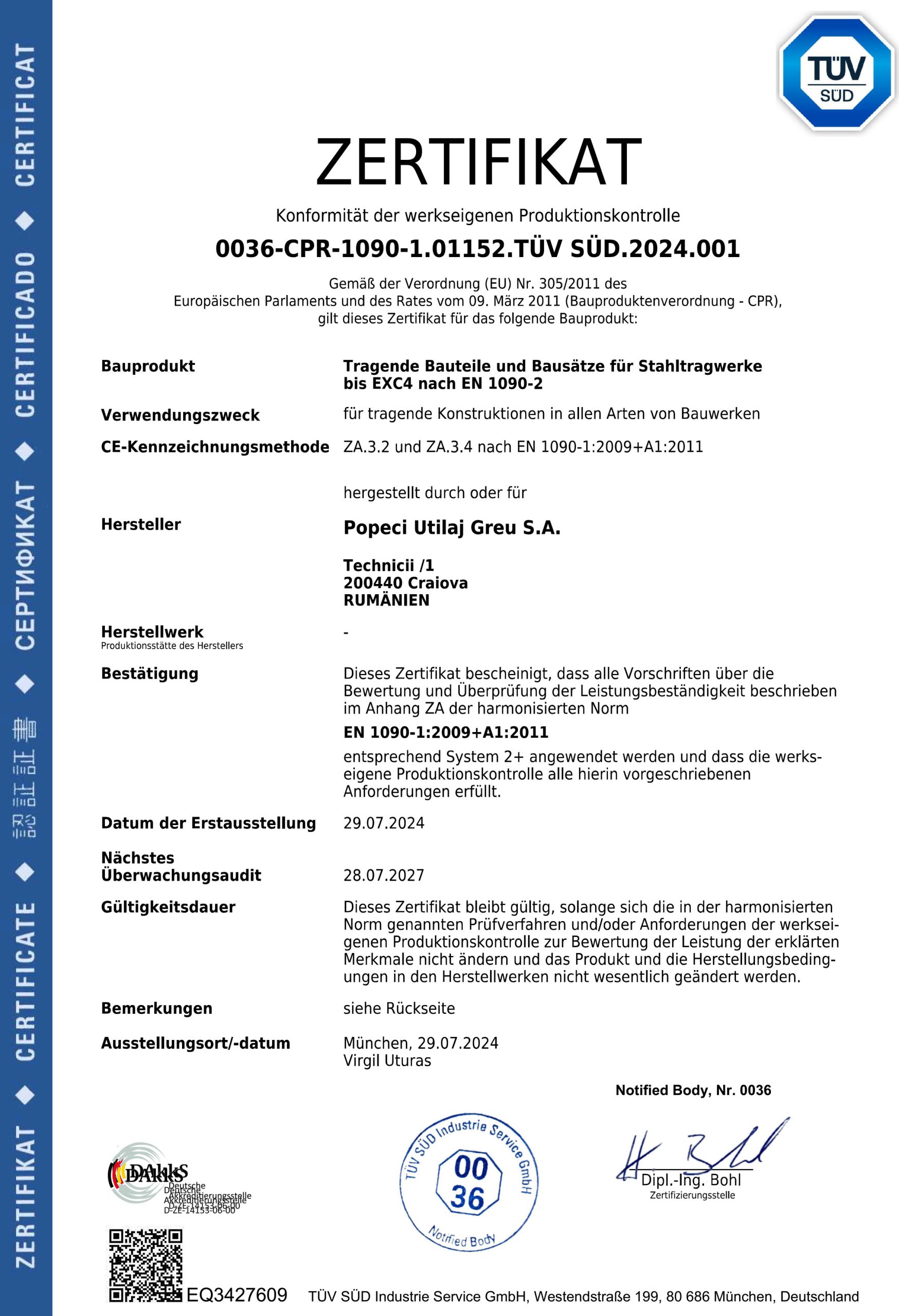

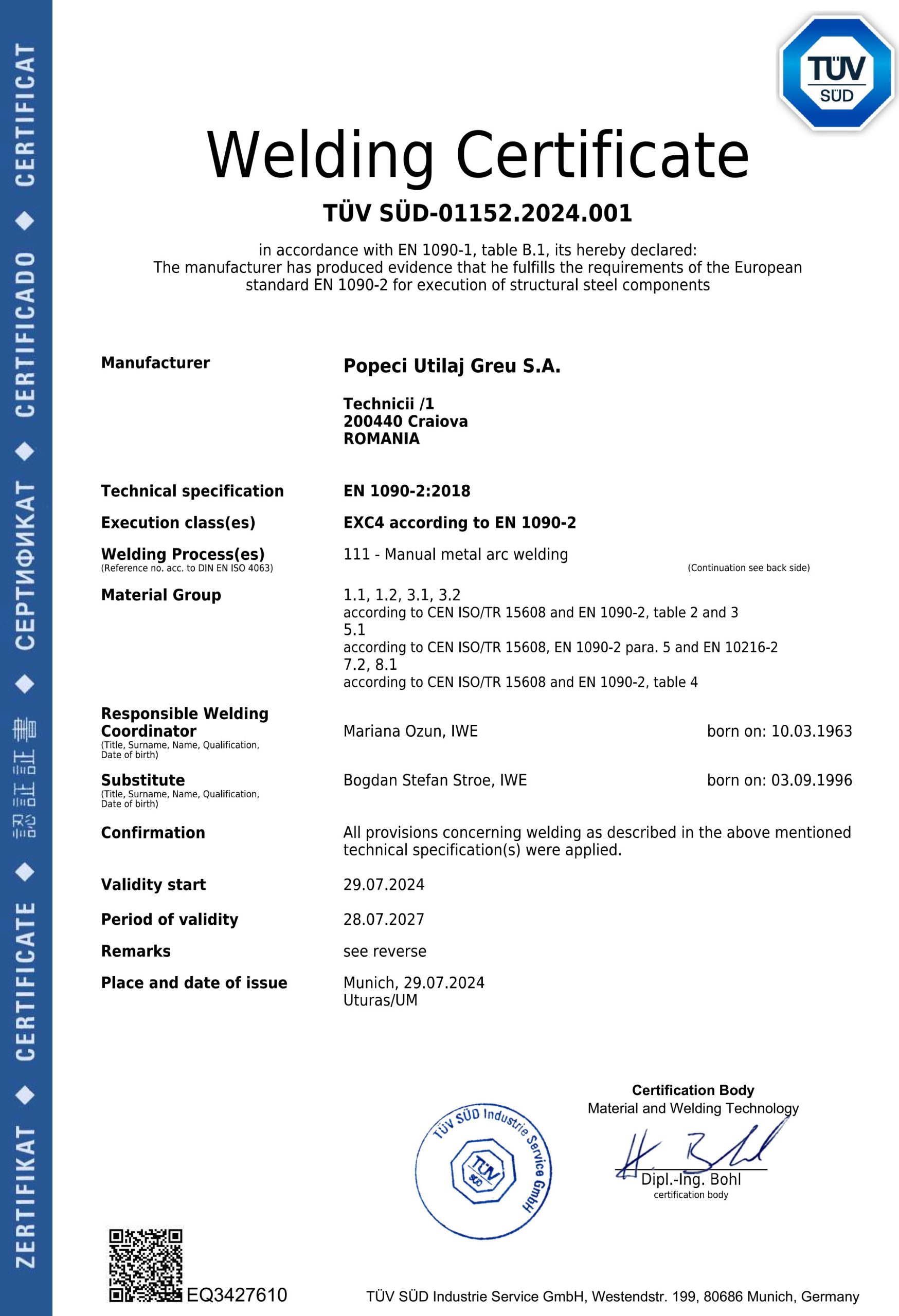

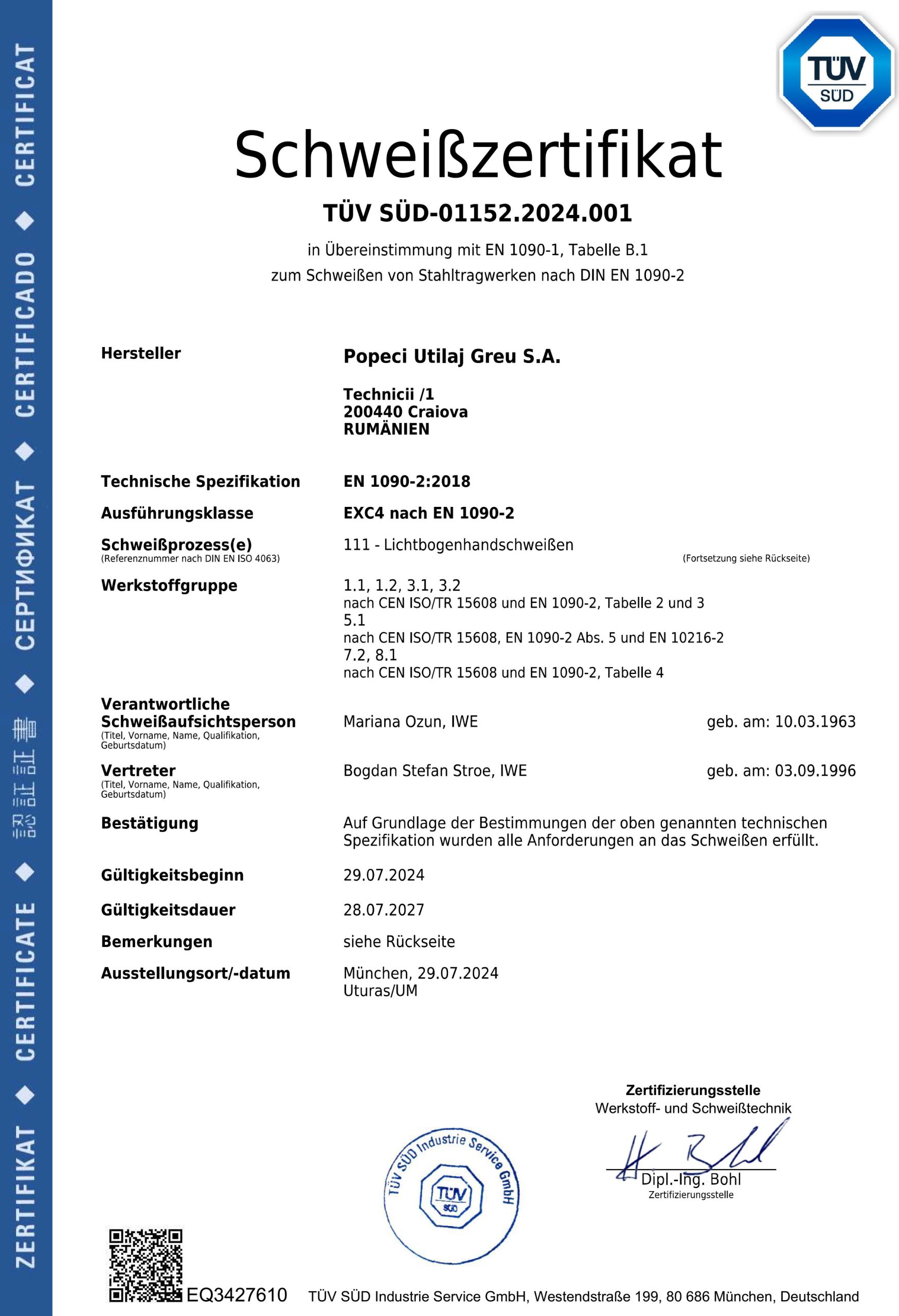

In 1995, Popeci Utilaj Greu, named then Intreprinderea de Utilaj Greu Craiova, was the first Romanian company in the field, certified by the prestigious Germanischer Lloyd company.

The Quality System begins with the product design phase, the selection of suppliers, the use of competitive machine tools and equipment, product testing with modern methods throughout the manufacturing flow, training and qualification of the company’s staff. All these are the secrets of our success.

Since 2008 the company has implemented and certified the Integrated Management System , which led to maintaining and improving our image on the domestic and external market.

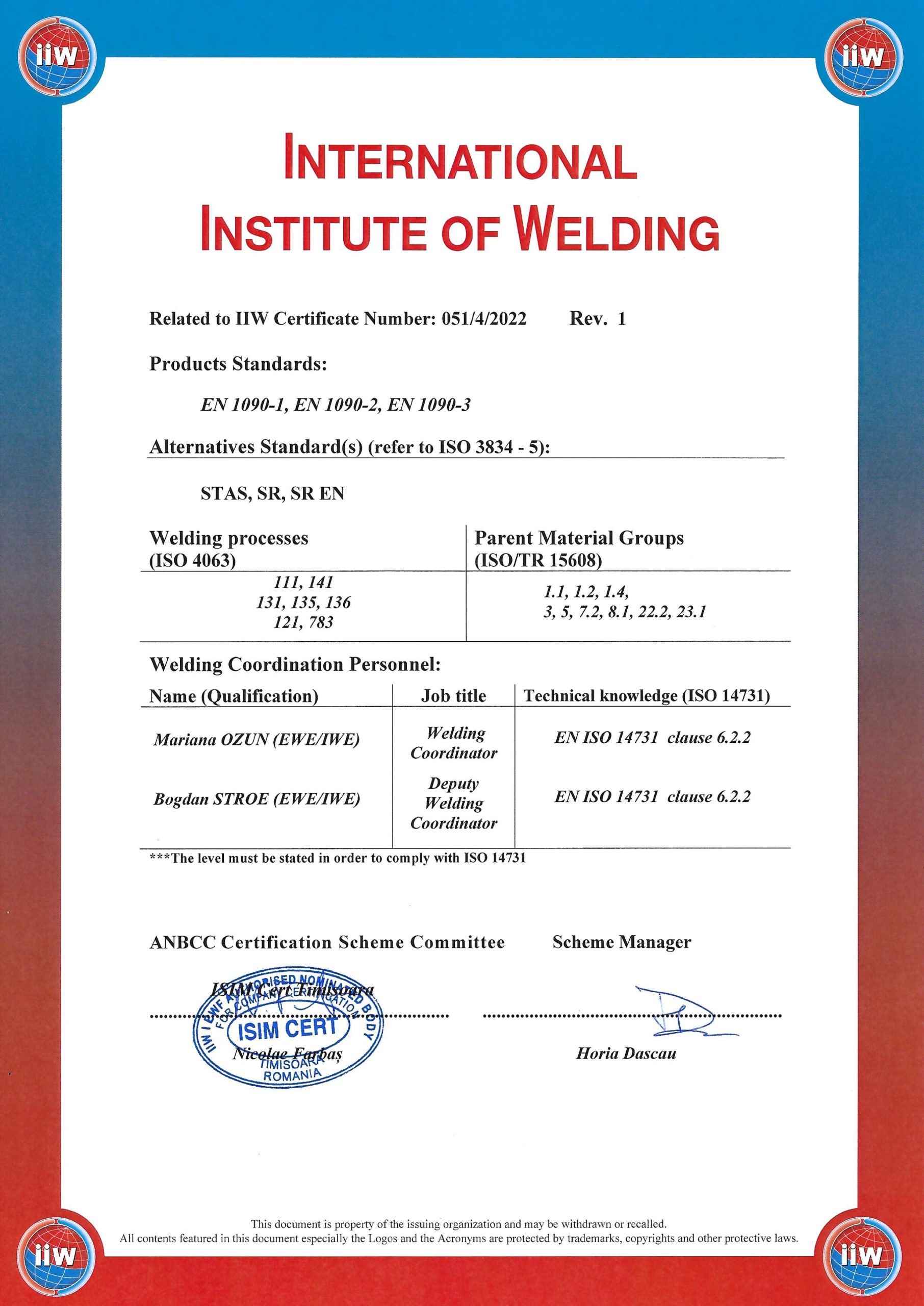

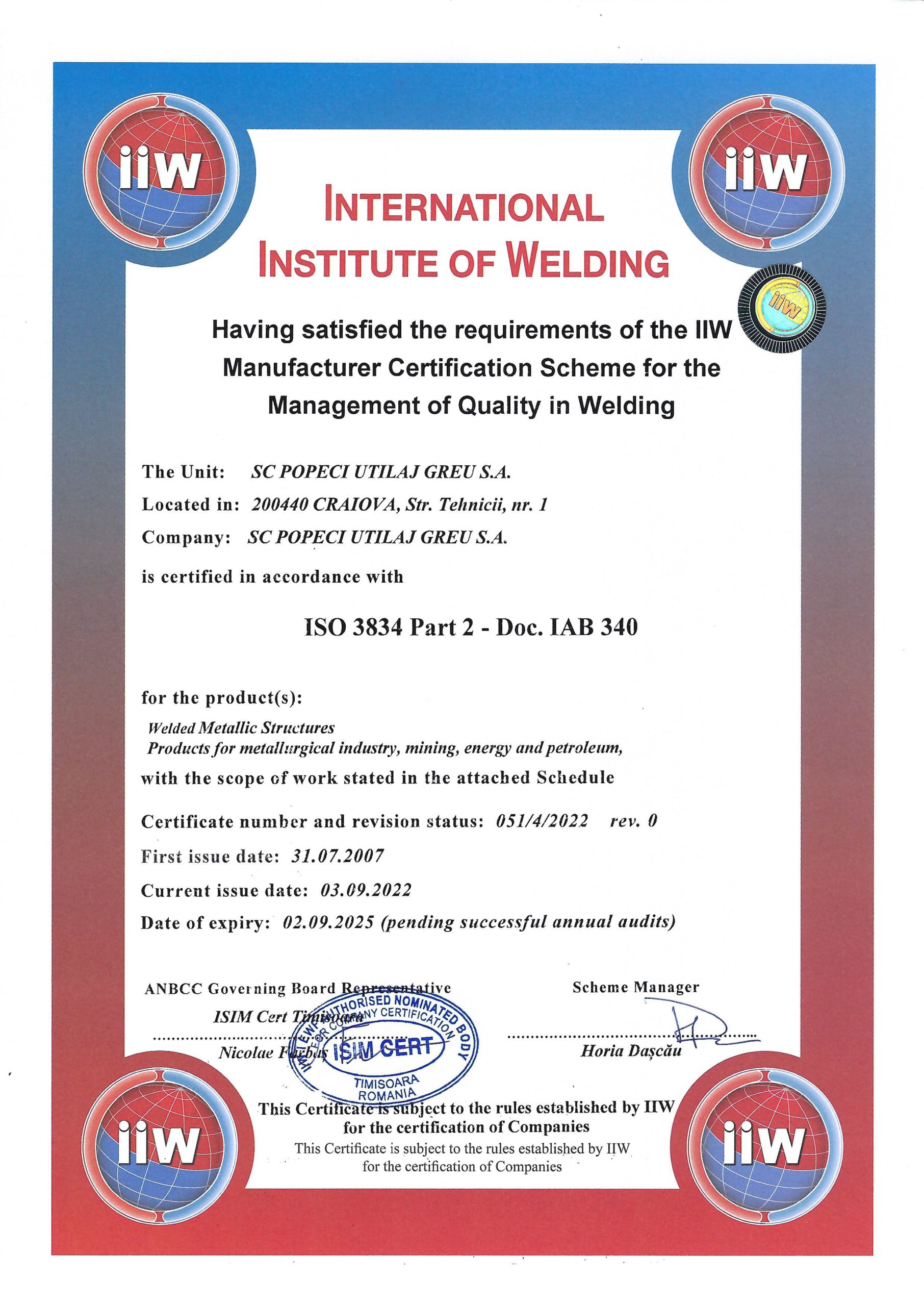

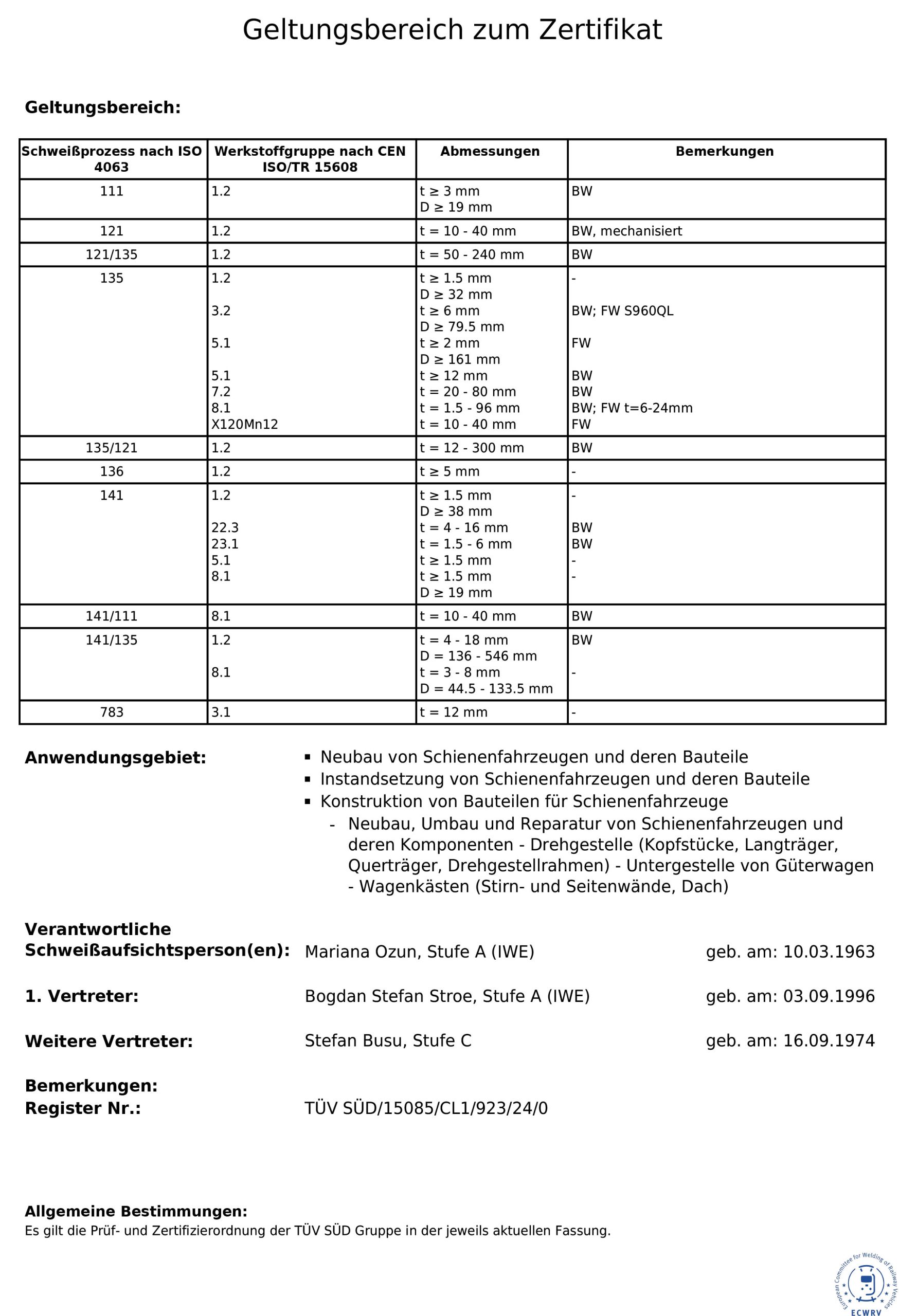

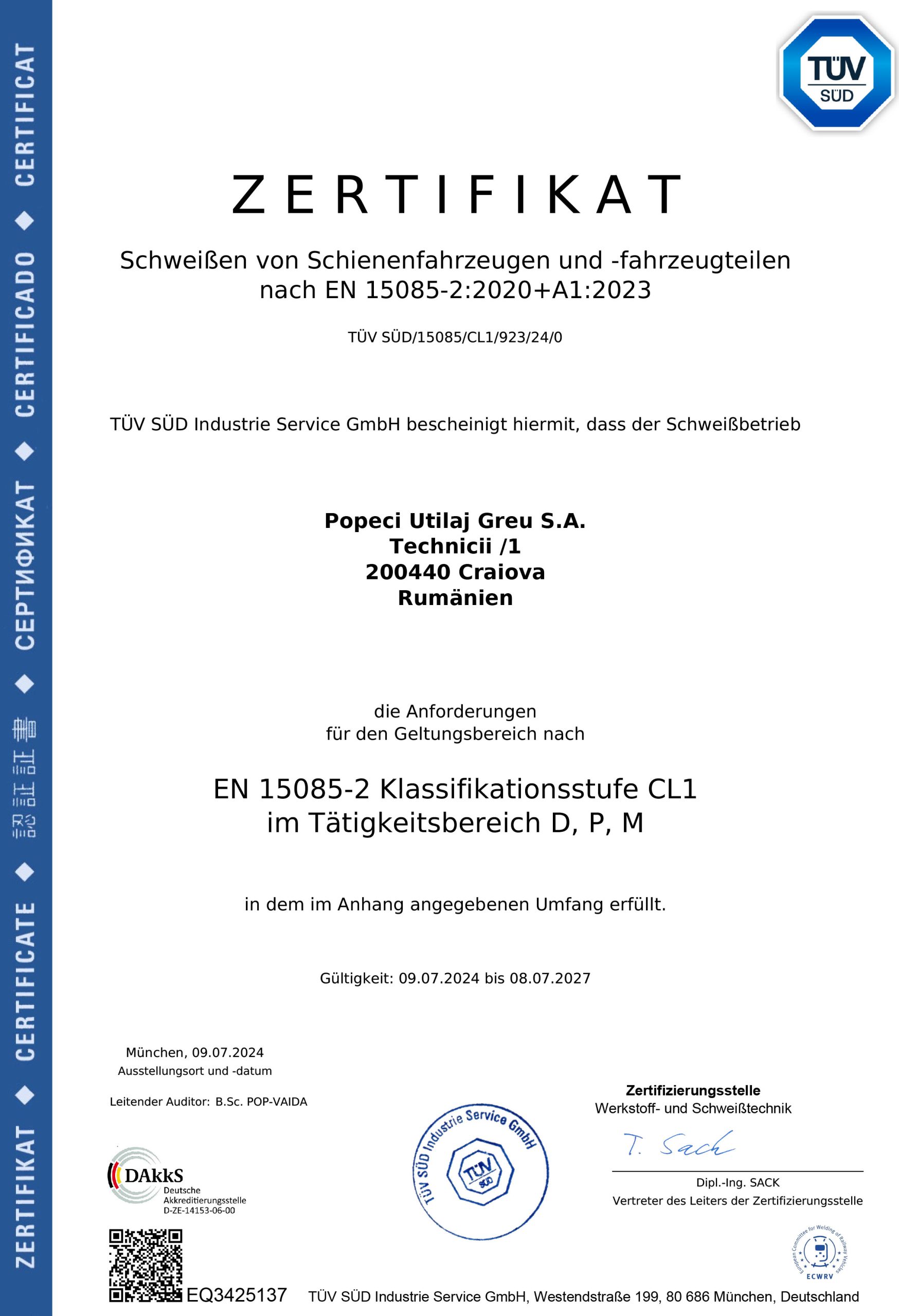

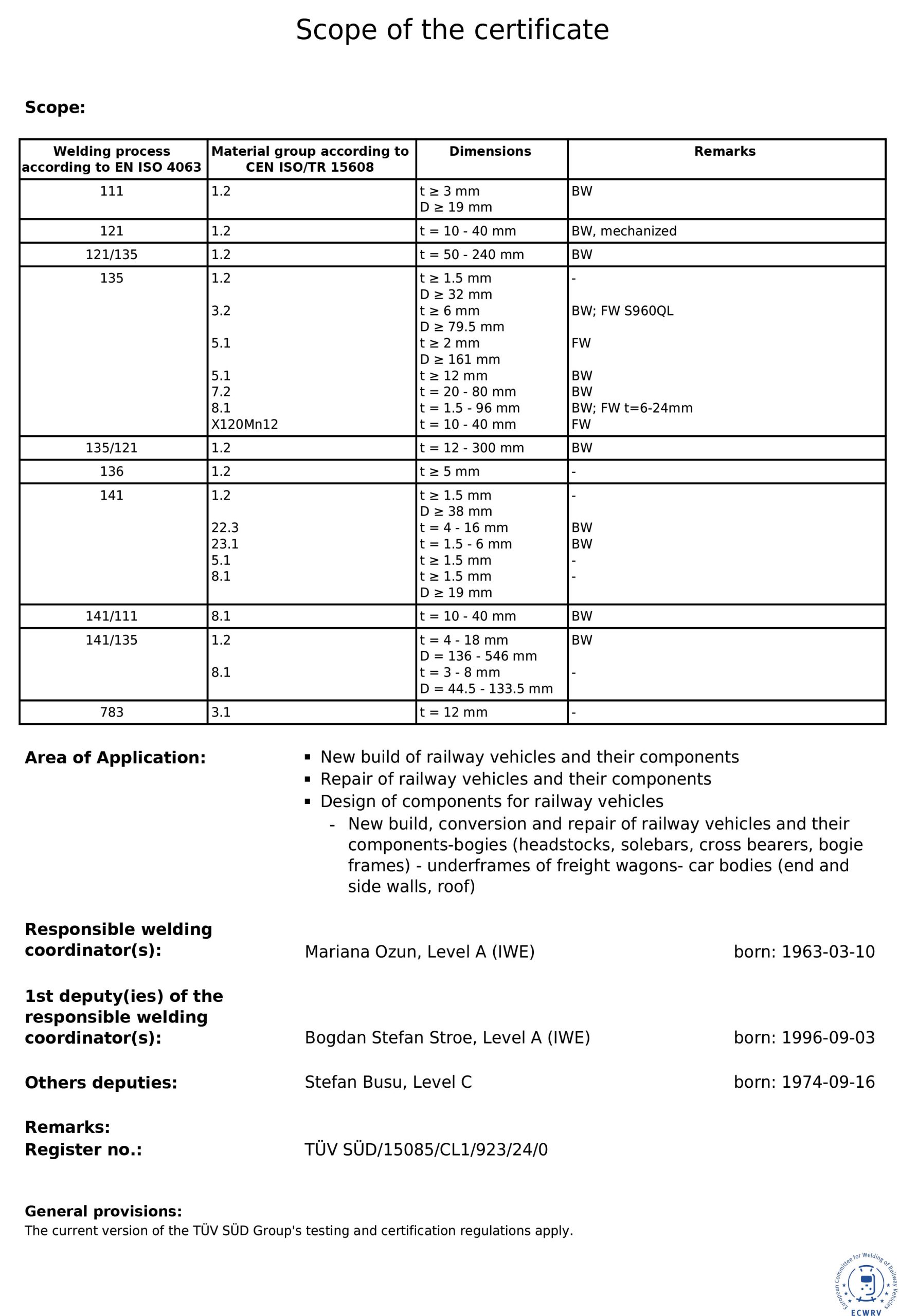

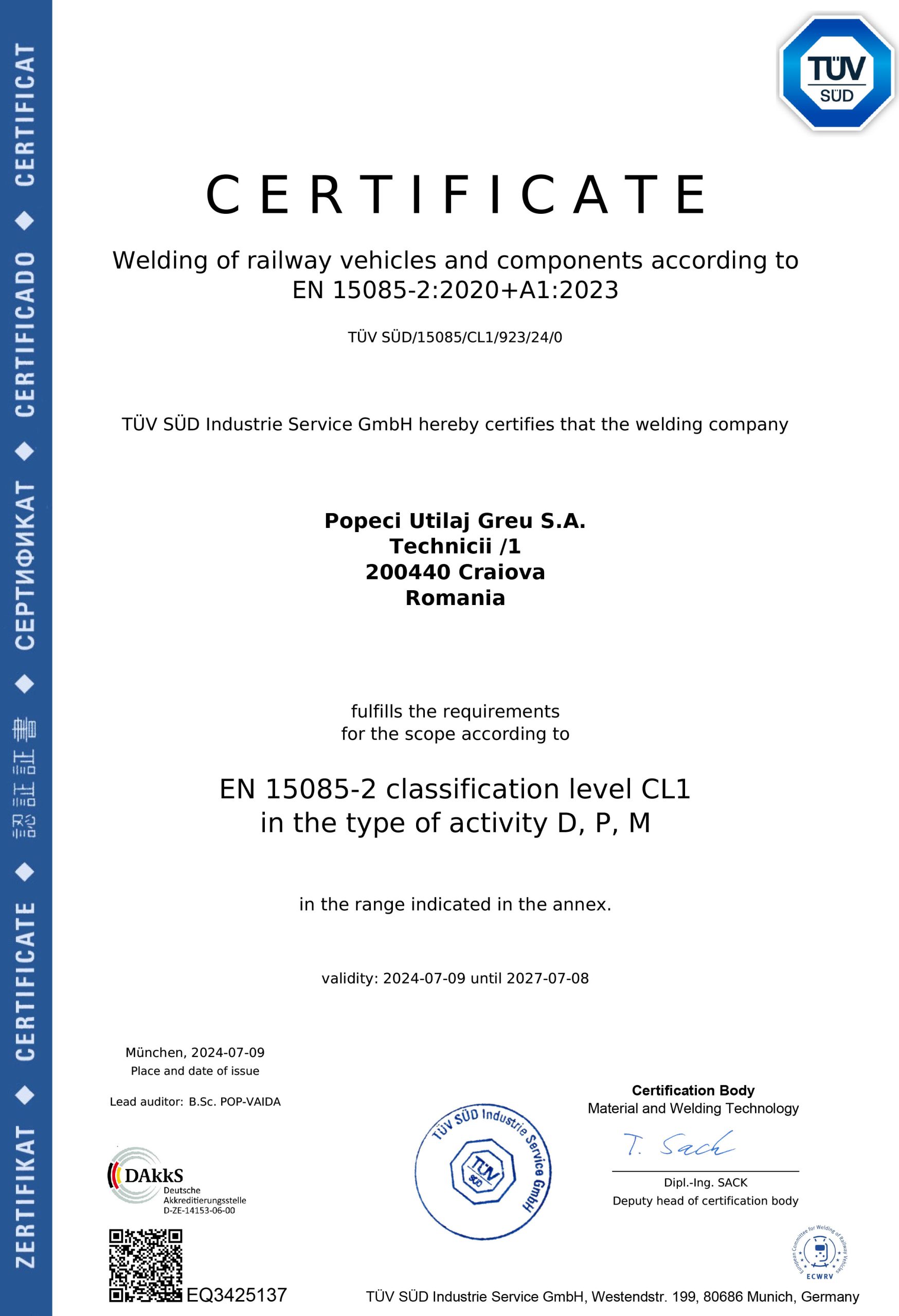

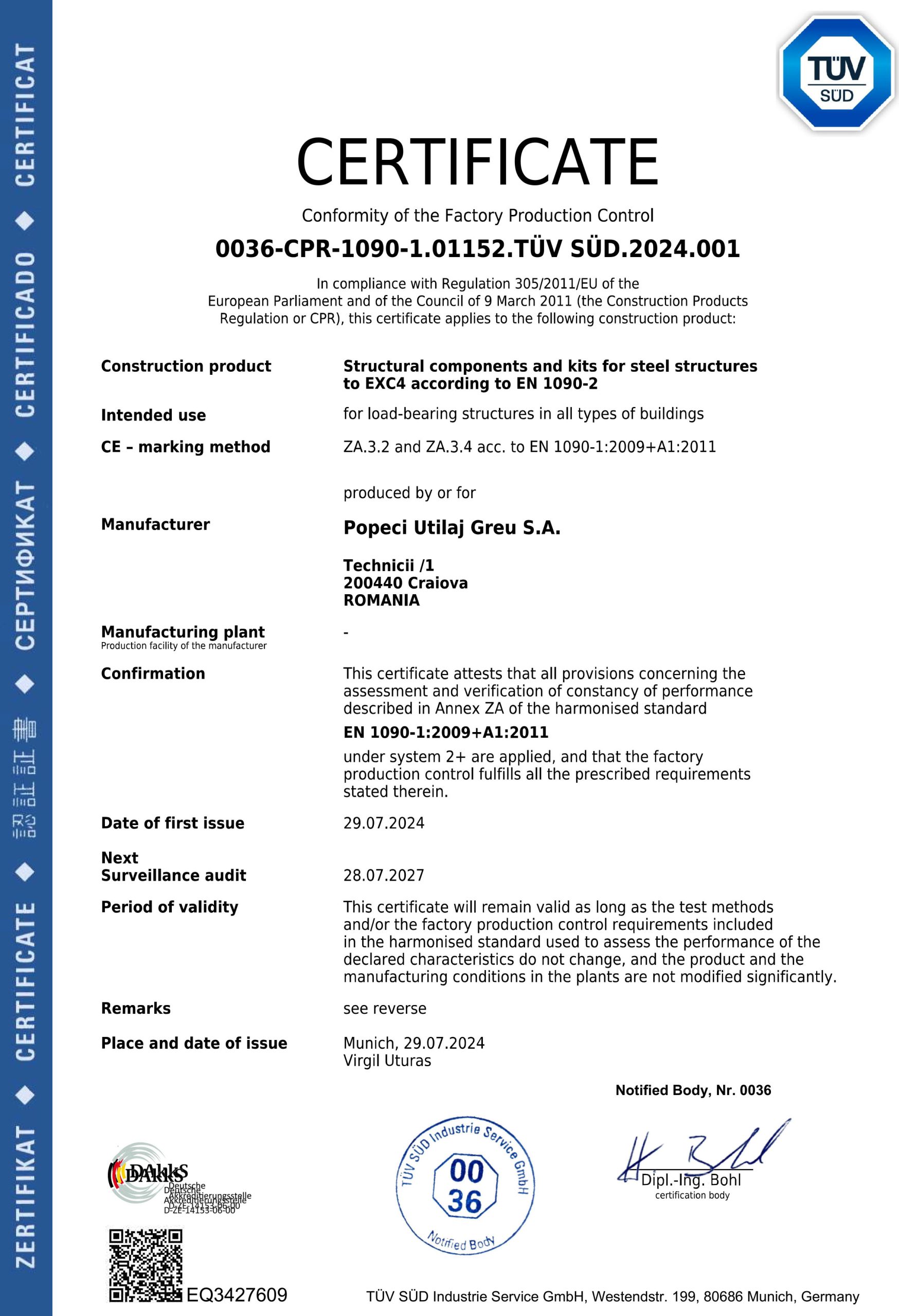

Also, the certifications and qualifications in the field of welding of metal structures, by DVS SLV Munich and ISIM Timisoara, as well as the authorization of the personnel (welders and controllers) according to the European standards. , is an asset of the company’s credibility for our customers.

The quality of our products is permanently tested in the company’s laboratories, which are provided with modern and high-performance equipment (FARO laser with interferometer, Articulated Arm, Spectrometer, portable devices for determining the hardness, non-destructive control devices).

They perform: chemical composition analysis for steels, cast iron, non-ferrous alloys, mechanical testing for steels and cast iron, US control for rolled, cast and forged products, control of welded joints on structures, metals, penetrating liquids, magnetic powders, X-rays and US , dimensional control and hardness control HB, HRC, HV.

All these are executed according to national or international standards, recommended by the client in the execution documentation or established by the design team of the company.